India's Leading Brand

Since 1946

One stop solution for Bearing Housing, Accessories and Casting Components.

State of Art manufacturing facilities.

700 +

Number of Products

50 +

Dealers & Distributors Network

40 +

Exporting Countries

4000 +

Satisfied Customers

Our Infrastructure

Moulding Facility

DISAMATCH C-20/24 High Pressure Moulding Lines with fully automatic SAND PLANT

Testing Facilities

Spectrometer having 6 channels with 17 elements. Ultrasonic testing equipment.

We at MASTA; always crave for continual improvement and excel the quality to meet and match with the footsteps of INTERNATIONAL STANDARDS OF QUALITY; have upgraded our foundry facilities with most high-tech machines and equipment for more productive and consistent quality of castings.

PRODUCT RANGE

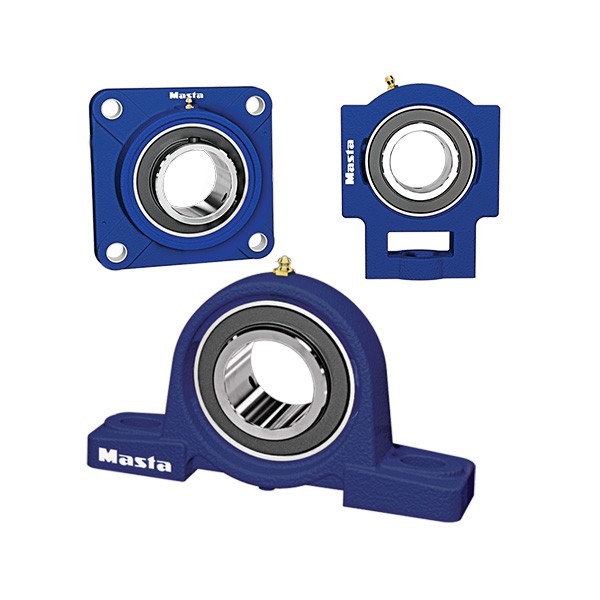

Bearing Housing

Wide range of series and designs of Bearing Housing/Plummer Blocks with all types of shaft seals and suitable for Grease lubrication, Oil lubrication and water cooling arrangement.

Explore

Pillow Blocks

Introducing the new range of Pillow Blocks by utilizing our own manufacturing setup. Compact structure, Ideal sealing, Easy to Interchange with reasonable range of self alignment.

Explore

Accessories

Masta manufactures all type of Bearing accessories such as Taconite Seal, Labyrinth Seal, V-Ring Seal, Four Lip Seal, Felt Seal. Adapter, Withdrawal and Hydraulic Sleeves. Lock Nut, Lock Washer and Locating Ring.

Explore

Castings

We develop and supplies Casting components as-per customer’s drawings or sample products available. Castings cab be supplied in graded Cast Iron, Ductile Iron, cast steel as-per customer’s specification.

Explore How we added value to our clients

Samrat Patel

Managing Director

Our Valued Clients

Client 1

Client 10

Client 11

Client 12

Client 13

Client 15

Client 17

Client 18

Client 19

Client 2

Client 3

Client 4

Client 5

Client 6

Client 7

Client 8

Client 9

Exporting Worldwide

- 🇨🇦 Canada

- 🇺🇸 USA

- 🇨🇴 Colombia

- 🇧🇷 Brazil

- 🇦🇺 Australia

- 🇳🇿 New Zealand

- 🇩🇪 Germany

- 🇫🇷 France

- 🇪🇸 Spain

- 🇮🇹 Italy

- 🇬🇧 UK

- 🇹🇷 Turkey

- 🇩🇰 Denmark

- 🇬🇷 Greece

- 🇦🇪 UAE

- 🇴🇲 Oman

- 🇶🇦 Qatar

- 🇮🇷 Iran

- 🇯🇴 Jordan

- 🇺🇬 Uganda

- 🇿🇦 South Africa

- 🇰🇪 Kenya

- 🇿🇲 Zambia

- 🇹🇿 Tanzania

- 🇻🇳 Vietnam

- 🇮🇩 Indonesia

- 🇲🇾 Malaysia

- 🇵🇭 Philippines

- 🇳🇵 Nepal

- 🇧🇩 Bangladesh