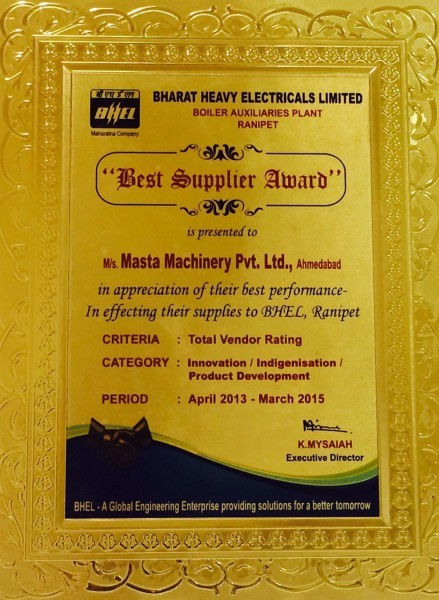

Masta Bearing Housing's product supremacy and global presence

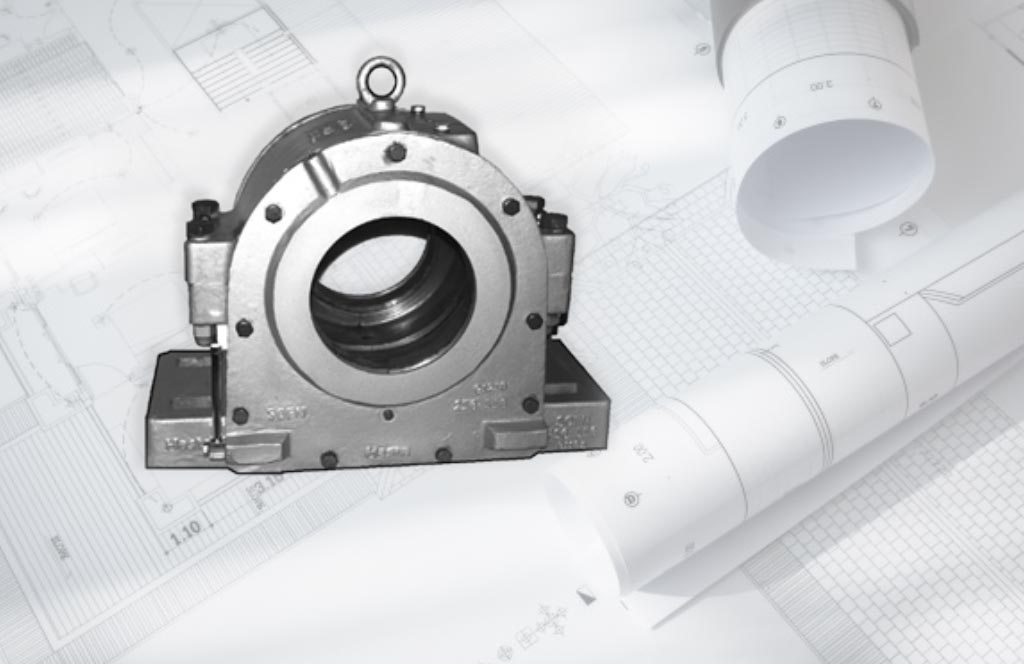

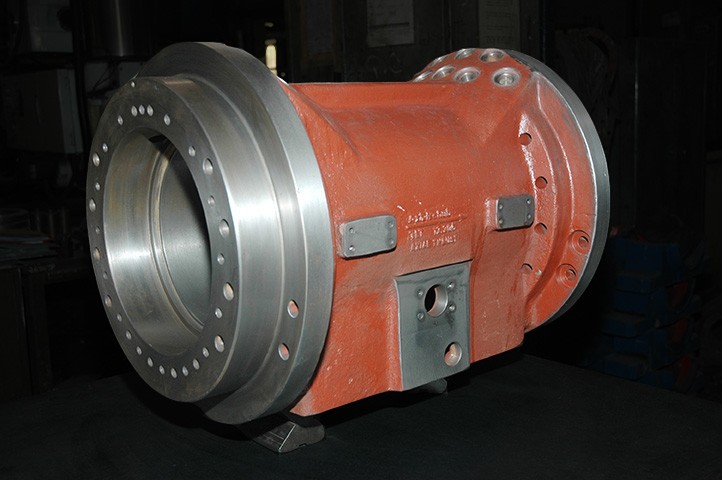

MASTA BEARING HOUSING PVT. LTD. Based in Ahmedabad, the progressive state of Gujarat is a distinguished name in the manufacturing of BEARING HOUSINGS. Starting with just two drills and a lathe machine in the year 1946, over the years MASTA has developed significantly with vastly equipped three foundries and state of art manufacturing facilities spread over more than 2.5 acres area and a foundry capacity of making more than 12,000 MT of castings and 2.5 lakhs of bearing housings per annum.